INDUCTION-TYPE ENERGY METER

Energy meters are the instrument used for the measurement of energy. Energy is the total power consumed over a time interval

i.e. Energy = power * time

A Single-phase induction type energy meter is the type of energy meter. It is one of the oldest types of energy meter and it is very commonly used for industrial and domestic ac circuits.

The induction energy meter works on the principle of induction instruments. In the induction-type energy meter, 2 fluxes are created in the windings. These fluxes made contact with a metallic disc and produce emf. This emf produces an eddy current on the body. The interaction of these fluxes and eddy currents produces torques that make the disc rotate.

Construction of induction-type energy meter

|

| Single Phase Induction Type Energy Meter |

Single-phase induction type energy meter has 4 main parts:

- Operating system

- Moving system

- Braking system

- Registering system

All of these parts of the single-phase induction energy meter are thoroughly explained below:

Operating system

Electromagnets are the main component of the operating system. So, the operating system consists of two electromagnets and these are known as shunt magnet and series magnet. The core of these two magnets is made of silicon steel laminations.

In a series magnet, the coil (having a few turns of thick wire) of the electromagnet is connected in series with the load. Whereas, the shunt magnet coil (having many turns of fine wire) is connected across the supply voltage.

A shading band made of copper is provided on the central limb of the shunt magnet. The purpose of applying this shading band to the shunt magnet is to bring the flux produced by the shunt magnet exactly in quadrature with the applied voltage.

Moving system

The moving system consists of a lightweight aluminium disc mounted on a spindle. The spindle is supported at the two ends, at one end by a steel pivot and on the other end, it is supported by jewel bearings.

The aluminium disc is placed in the air gap between the series magnet and the shunt magnet. The placement of the disc is so positioned that the disc intersects the flux produced by both magnets. And the change in the magnetic field induces the eddy current on the disc.

So, when the fluxes produced by the magnets and the induced eddy current on the disc interact, it produces a deflecting torque on the disc.

The aluminium disc is placed in the air gap between the series magnet and the shunt magnet. The placement of the disc is so positioned that the disc intersects the flux produced by both magnets. And the change in the magnetic field induces the eddy current on the disc.

So, when the fluxes produced by the magnets and the induced eddy current on the disc interact, it produces a deflecting torque on the disc.

Braking system

The braking system consists of a permanent magnet placed near the aluminium disc. The relative motion of the aluminium disc and the permanent magnet induces an eddy current in the disc. The eddy current interacts with the permanent magnet flux and produces braking torque.

The braking torque is proportional to the speed of the rotating disc. The permanent magnet is adjustable, therefore the braking torque can be adjusted by shifting the permanent magnet to different radial positions w.r.t the disc.

Registering system

The function of the registering system is to continuously record a numerical value that is proportional to the number of revolutions made by the disc. The rotation of the main disc can be transmitted to different pointers of the different dials to register meter readings.

The meter reading can be determined by multiplying the number of revolutions with the meter constant. The meter reading is obtained in kilowatt-hours (kWh).

K= N/Energy= Number of revolutions/ kWh

Working of induction type energy meter

The induction-type energy meter consists of an aluminium disc placed between 2 electromagnets (series and shunt magnet). The series magnet has a current coil and the shunt magnet has a pressure coil. As pressure coil winding has a large number of turns of fine wire to make it highly inductive.

When voltage is applied across the pressure coil induces flux which lags 90° to the flux produced by the current coil. This produces an eddy current in the disc. The interaction of the eddy current and the magnetic field exerts a torque on the disc. Due to this torque disc starts rotating.

The registering system counts the revolution of the disc and the permanent magnet further controls the rotation of the disc.

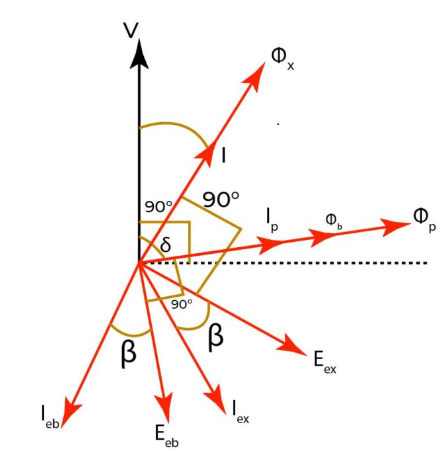

Phasor diagram and explanation

Phasor diagram of a single-phase induction-type energy meter is shown below:

Let,

V = supply voltage

I = load current

Φ = phase angle of the load

β = phase angle of an aluminium disc

α = phase angle between shunt and series magnet fluxes

Δ = phase angle between a supply voltage and pressure coil

When the supply voltage is applied current Ip flows through the pressure coil and produces flux Φp that is in the same phase as Ip. the flux Φp is divided into two parts Φa and Φb. The major portion of the total pressure coil flux Φa passed through the side gaps due to low reluctance. The remaining portion of the flux Φb passes through the disc and is responsible for the production of torque on the disc.

The flux Φb is proportional to Ib thus it is also proportional to supply voltage V and lags by 90°. Thus the flux Φb induces eddy emf Eep in the disc, which further induces eddy current Ieb. The eddy current Ieb will lag behind the eddy emf Eeb by an angle β.

The load current flows through the series magnet current coil and produces flux Φx. Flux Φx is proportional to the load current and in phase with it. Similarly, this flux also induces eddy emf Eex in the disc, which in turn induces eddy current Iex in the disc.

Now, the eddy current Iex interacts with Φb and produces torque. Similarly, the eddy current Ieb interacts with Φx and produces another torque. Both the torques are opposite in direction. So, the resultant torque is the difference between these two torques.

Resultant deflecting torque on the disc due to both fluxes is given by

Td ∝ ( ΦbΦxω/Z). sin α cos β

Td = K1 ( ΦbΦxω/Z ). sin α cos β

Where K1 is a constant

Driving torque can be further written as

Td = K1 ( ΦbΦxω/Z ). sin (δ-Ѳ) cos β

Since Φb∝ V and Φx∝ I

Td = K2VI ω/Z. sin (δ-Ѳ) cos β

if Z, ω, β are constants

then,

Td = K3 VI sin (δ-Ѳ)

If N is the rotating speed of the disc, then the braking torque

Tb = K4N

At a steady state, the driving torque must be equal to the braking torque

K4N = K3VI sin (δ-Ѳ)

N = KVI sin (δ-Ѳ)

If δ = 90°

Then speed of the disc

N = KVI sin (90°-Ѳ) = KVI cos Ѳ

N = K * power

Total number of revolution = ʃNdt = ʃKVI sin (δ-Ѳ)dt

If δ = 90°

Total number of revolutions = K ʃVI cosѲdt

= K ʃpower * dt

= K * energy

Errors in induction energy meter

Phase angle error

The induction energy meter indicates accurate energy only if the phase angle between the pressure coil flux and supply voltage is 90°

Error due to change in temp.

Errors due to temperature variation in induction-type meters are usually small as the various effects tend to neutralize each other. An increase in temp. reduces the driving torque. And the flux of the brake magnet also reduces due to an increase in temperature, which further reduces the braking torque.

Thus the various effects caused by the temperature increment tend to neutralize each other.

Error due to overload

At higher loads in induction-type energy meters, the braking torque overpowers the deflecting torque and the energy meters tend to rotate at a slower speed due to which the meter reads lower than the actual reading.

Advantages of induction energy meter

- This meter is cheap.

- It is used universally for ac measurements

- It has high torque to weight ratio

- It requires very low maintenance and can be used for a long time

Disadvantages of induction energy meter

- This type of meter can be used for ac measurements only

Comments

Post a Comment